The development of technology throughout the years has increased the quality of life. But it seems that we can never get enough. Whenever we are browsing the market, we focus on buying the fastest, newest, and most efficient products.

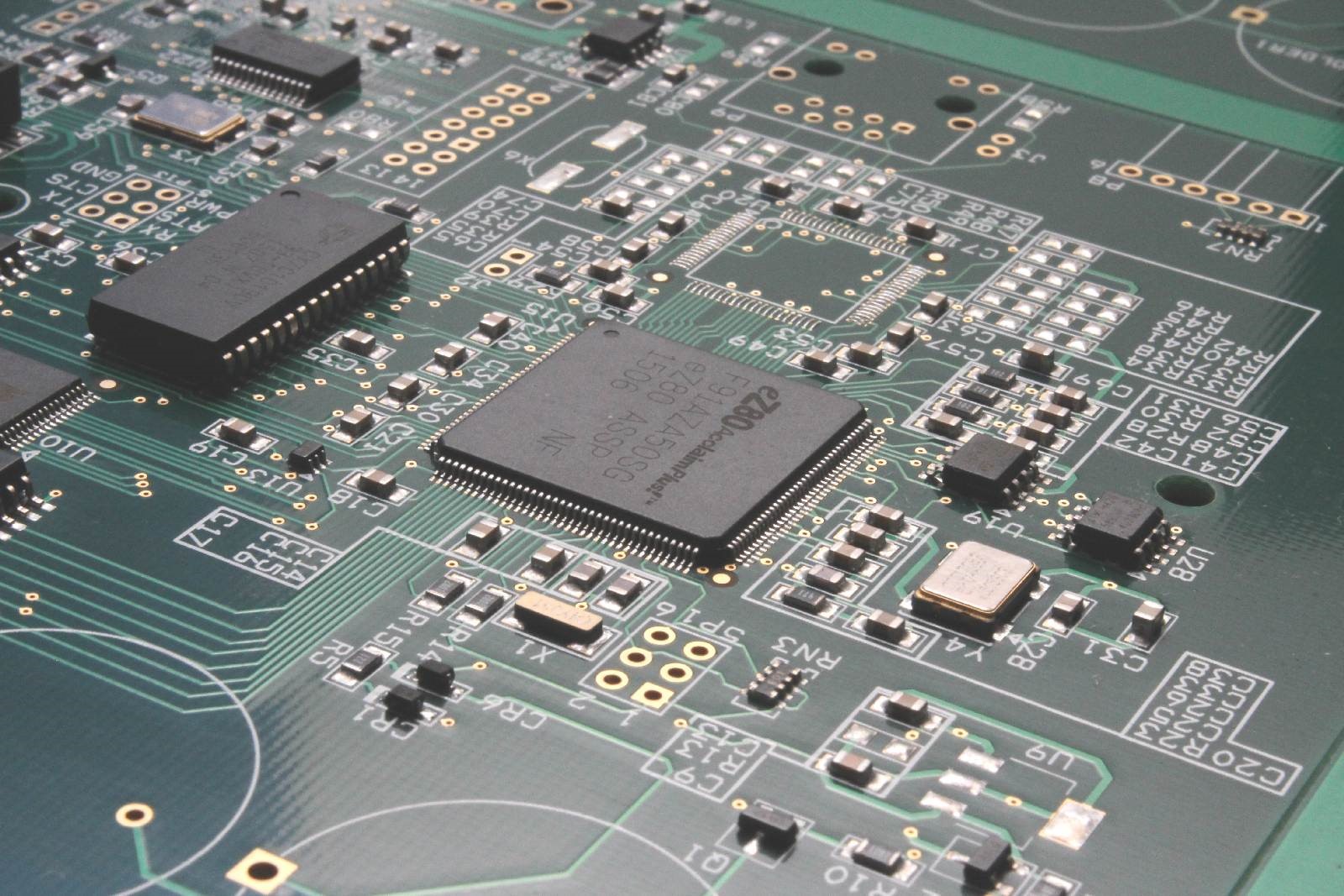

Whether it is a non tactile membrane switch, or STM32, the importance of deciding which electrical components you will use in your printed circuit board (PCB) is unquestionably essential. It may be a tedious job to research which is the best solution for you, but is worth it.

This desire for something better and new has made the manufacturers face a problem. Volume, weight, cost, and quality of electronic parts have peaked, and the products, made with the conventional manufacturing methods, were the best they could be.

In the 1960s, a new and innovative method was invented called Surface-mount technology (SMT). The process of mounting or placing electrical components directly on either side of the PCB is called Surface-mount technology. The popularity of this kind of manufacturing process hadn’t raised until the 1980s when a large number of produced electronic assemblies were made with the help of SMT.

So, what were the advantages of this technology that made it so popular today? Click on the link to find more on this https://medium.com/@tektrong/advantages-disadvantages-of-surface-mount-technology-smt-100e0f16a17.

Design

The main benefit of Surface-mount technology is definitely its tiny and practical design. Unlike the through-hole technology, this manufacturing process’s ability to be applied on either side of the PCB can save space and lower the price of transportation.

A significant contribution to SMT’s design is the potential use of hybrids, which allows the manufacturer to use a combination of plastic and ceramic materials and lower the cost of production.

Size

While the design allows mounting on both sides, it also allows the electronic components to build closer and achieve higher density for the connections, making them better than through-hole technology, which blocks the space inside the PCB.

This feature gives the manufacturer more components per unit area and significantly more connections per electronic component, making the PCB lightweight and minute-sized.

EMC and frequency performance

This features like smaller design and package result in better Electromagnetic compatibility performance, hence reducing the possibility of non-desirable electromagnetic interference or potential damage on the equipment itself.

Due to the miniature size of the parts, low levels of inductance and resistance are possible, allowing higher frequency performance as well as faster speeds. Read more here.

Mechanical performance

Light-weighted parts are prone to better vibration circumstances and superior mechanical performances. These advantages save money with a long life span of the electronic components on the PBC.

The design has proven its own advantages and made SMT an attractive part of modern technology. Although PCB density and size are a relevant factor for putting the product for sale, the production also plays a significant role in defining the price and quality of the same product.

Faster, cheaper, and efficient production ways are made to deliver innovative products on the market, looking even more attractive for the buyers!

Easier, cheaper and faster production

The use of drill to attach the required electronic components, a thru-hole technology, instead of mounting is long-lasting but costly. The automated technology and equipment that make the surface mount technology made it easier to improve and develop while reducing labor costs and significantly reducing the chance of an error.

The automated joining of electronic components contributes to faster production and neat automatic correction of the molten parts. Developing surface-mount packages (SMD) with high and good thermal conductivity is essential for growth in this field. The complexity of the SMD varies depending on consumer requirements. More complex SMDs have less space and, while working, produce more heat, shortening the package’s life span.

It seems like the perfect solution to many problems. Although its functionality is attractive, great attention Is required for mounting and joining the parts. The process requires great precision for a neatly done job. Thankfully the demand for this technology only increases, which widens the competition on the market and allows you to choose from the best.

Nowadays, companies offer many reasons to choose them, providing high-quality standards, a long history of experience, excellent support, and low chances of defective products. SMT is used widely for economical, efficient, and practical PCB assembly.

Like this article? Share with your friends!